Use of Middle East Star Drill Co. Whipstock and milling tools offers to operators new alternatives to grass roots Directional & horizontal wells. The Middle East Star Drill Co. Whipstock is a quality built tool designed to prepare or “cut a window” in the casing of your existing well bore. Our Whipstock can be utilized in a vertical or high angle hole for sidetracking the original well bore or in preparation for directional or horizontal drilling. The reduction in cost per foot per recoverable barrel of oil has brought a new focus on oil in place reserves. The Middle East Star Drill Co. whipstock is designed to cut a window in the casing of the existing wellbore. This design allows the tool to be run in vertical or high angle holes. We have two type of whipstock:

1- One Trip Case Hole Whipstock :

In this type to save time, systems can accomplish all sidetracking tasks in one trip. On the first trip in the hole, both styles of the Whipstock are lowered by way of the starting mill, orientated to your predetermined direction, anchored, and initial milling of the casing window is begun. The completion of the casing window is achieved on subsequent mill runs. In this system following operation done in one stage:

Start the window mill

Complete the mill

Clean up

2- Two Trip Case Hole Whipstock :

2-1- Method of Application for Window Cutting, There are 5 Steps:

Initial step, clamping, cutting through, window service and drilling testing. Operating parameters for every steps as per manufacturer and supervisor Guideline.

Connect the milling cone for sidetrack window-cutting and drilling tools as their designs require.

Drill down the drilling tools to 2~3 meters up the deflector, speed of drilling down should be not faster than 30 pieces/hour. Connect the Kelly bar.

Run the pump to circle the drilling fluid, start the rotary table at a low speed, and record its hanging weight, drill down the drilling tools slowly until the hanging weight changes. Record its depth at this moment.

Start the construction of initial step, clamping, cutting through by the parameters of milling cone.

Trip the drilling tools slowly for the window service as stipulated until there is no jam and blockage.

After window service, start the tentative drilling.

After all the above mentioned operations, first, flush the wall fully, and then put the drilling tools out of the hole.

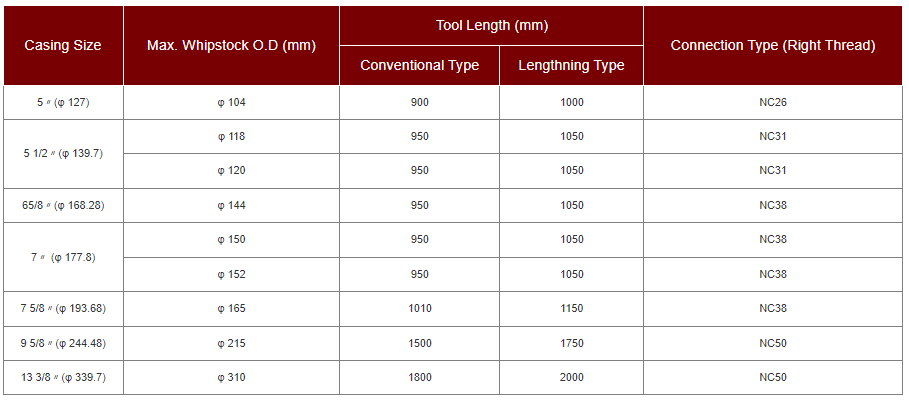

2-2- Basic Parameters and Performance Data:

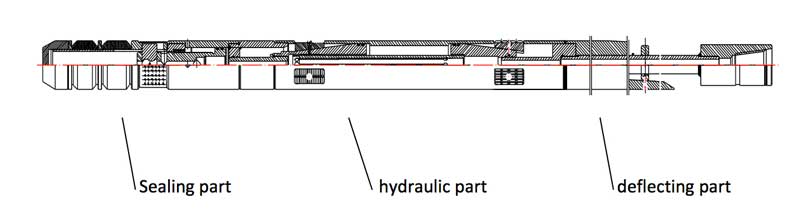

The main structure consists of deflecting part, hydraulic part and sealing part (optional) as following pictures.

Milling Structure for Window Opening

Sidetrack window-cutting make use of milling cone and deflector inside of the case pipe. By design, the shape, cutting bezel and alloy are optimized. The milling cone for sidetrack window cutting can finish window cutting and window service at one time together, speed up the construction, and meet the requirements of site work.

The milling cone for sidetrack window-cutting is a combined type. There are three stages: window cutting, window service, stabilizing window. Use proper piece of hard alloy and hard alloy electrode according to different stages, make the best matching between speed and service time to the maximum extent.