MWD Services

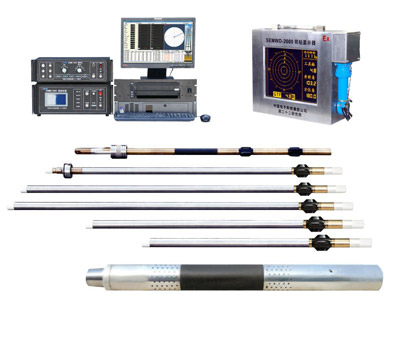

Middle East Star Drill’s (MSD) MWD system consist of two type of famous MWD:

APS MWD (Positive)

HILAN (Positive)

Middle East Star Drill’s (MSD) EM-MWD system consist of:

APS EM-MWD System

CEM EM-MWD System

The APS & CEM EM is an MWD tool that combines the latest in electromagnetic frequency based technology with a durable and efficient design, providing an effective solution for EM applications.

Measurement While Drilling (“MWD”) systems are installed in the drill string to provide real time measurements of basic trajectory parameters such as inclination, direction, tool-face and temperature. Additional sensors such as pressure, gamma-ray and resistivity may be added depending upon the specific application.

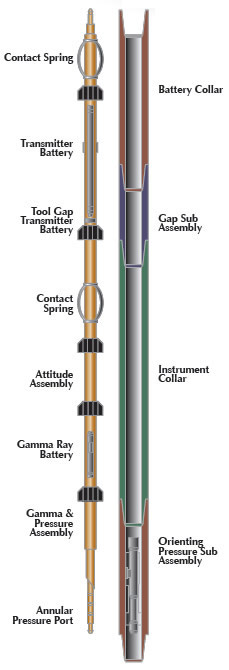

MWD tools consist of three basic sections:

Power Supply – Most tools are powered by lithium batteries or in some cases down-hole generators (turbines).

Sensor Section – Hole trajectory is measured by a sensor stack that has three accelerometers and three magnetometers. The inclination and roll (gravity tool-face) of the tool is made by gravity based measurement devices called accelerometers. Simply stated, they can be considered to be an electronic plumb-bob. Magnetometers measure the earth’s local magnetic field. Combined with inclination sensors the tool can provide a reference direction to magnetic north. This is corrected for true north by adding the localized value for magnetic declination. Other sensors such as pressure, gamma-ray, and resistivity are typically housed in separate dedicated tool sections.

Transmitter – Current MWD tools transmit in two basic manners, by sending pressure waves through the drilling mud (mud pulse) or by transmitting electromagnetic (EM) signals through the earth to surface.

Mud Pulse System

Mud pulse tools operate by either opening or closing a valve in the tool that creates either a pressure surge (positive pulse) or drop (negative pulse). Mud pulse systems are a reliable transmission method.

Gamma

Gamma ray sensors measure the natural radioactive emissions from isotopes of potassium and the uranium and thorium series contained in, or absorbed into the mineral components of surface rocks.

Middle East Star Drill’’s MWD system consist of two type of famous MWD:

APS MWD (Positive)

HILAN (Positive)

All type can work up to 150 °C.

EM-MWD Services

Electro-Magnetic MWD systems:

Use the same basic sensors and power supplies as the mud pulse systems. The main difference is in the transmission of data. Rather than using the drilling mud to send pressure waves, the tool sends either a magnetic pulse or electrical current through the ground to the surface. On surface the data is received through ground antennas and the data processed. EM systems are significantly faster (10x) than conventional mud pulse. In addition data can be sent at any time (not just when the rig pumps are circulating). The net result is faster overall drilling times. In addition the EM systems are the only practical method to drill underbalance wells involving the use of air, nitrogen, and foam. EM systems have no moving parts and do not create significant restrictions in the drill string. As a result the reliability is significantly higher, and damage from erosion caused by drill solids is minimal. EM tools do have depth limitations which are a function of how much power can be supplied by batteries for the duration of the drilling interval, and at higher power settings the battery costs may be significant.

Electromagnetic Measurement While Drilling “EM MWD” Services:

The EM MWD tool is a wireless MWD System which utilizes low frequency current-loop signals to communicate data to the surface. The EM tool is installed in the BHA and injects electric current into the formation downhole while drilling. An antenna (ground stake) is driven into the surface, which measures the voltage differential (potential) between the stake and a line tied into the casing on the drilling rig. This signal is processed thru surface computers to decode the downhole data. EM signals are not affected by the drilling mud properties or rig pumps and have a significantly higher data rate than mud pulse systems.

Applications:

Underbalanced Drilling

Coal Bed Methane

Lost Circulation

Vertical Control Drilling

Directional Drilling

Horizontal Drilling

Re-entry Wells

Contaminated mud systems

Features:

The EM MWD tool can be operated at a variety of frequencies, allowing for either high data rate, or extended depths (over 3,500 m) without the need for repeaters or long wire systems. Advanced digital filtering techniques allow two or more rigs to drill on the same pad without interfering with each other’s signal transmission. The tool has directional, gamma ray, and pressure sensors, making it versatile enough to accommodate most of your directional and underbalanced drilling requirements. The wireless communication operates independent of rig pumps and creates virtually no additional pressure restrictions in the BHA. Access to the microprocessor can be made through a unique side entry data port on the rig floor. Simply plug into the tool to program it, retrieve recorded data, or put it to sleep between wells to conserve battery life. The instrument section may be left in the non-magnetic collar between wells or during casing breaks to save rig time handling tools. The EM tool has become a full service tool and able to have “talk down” capability. The tool can be fully controlled from the surface, changing data rates, transmission formats, power levels etc, while drilling.

Directional survey and steering only or optional gamma logging configurations with annular pressure capabilities are available. Programmable low frequency transmission and high-power output can significantly reduce noise sources for a clean signal. No mechanical parts reduce transmission problems in the presence of LCM. Down hole tool is fully retrievable and re-insertable for added confidence in lost in hole conditions. Continuous transmission and automatic resynchronization of survey and steering sequences eliminates the need to cycle pump for survey acquisition or tool face mode.

Applications

Features & Benefits

High operating temperature (175C) and pressure (20,000psi)

Wireline retrievable and reinsertable design (minimum 2.25in I.D.)

Available real-time gamma and annular pressure for LWD

Downlink capability for frequency and power settings

High-speed data transmission

Data transmission independent of pump pressure

Reduced lost circulation material (LCM) restrictions

Programmable frequency settings for noise elimination

Reduced mechanical parts for improved reliability and ruggedness

Continuous survey and steering frames automatic resynchronization

Specifications:

Directional, vertical, horizontal and re-entry wells

Aerated and contaminated drilling fluids

Underbalanced drilling (gas, air, foam)

Lost circulation zones

High rate of penetration (ROP) applications

Coal bed methane (CBM)