home

Bit Sales & Engineering Services

A-Bit Exclusively Sales of HR BITS (HEBEI RUISHI BITS) in Iran:

HR BITS (Hebei Ruishi Bits Manufacturing Co., Ltd) was established in 1990. It is engaged in diamond drill bit and drilling tool research and development, design and manufacture, sales, and service of specialized companies.

As the first-grade supplier for Sinopec, CNPC, and CNOOC, Ruishi’s products are widely used in the Tarim, Tuha, Changqing, Dagang, Sichuan, Zhongyuan,Jidong, Huabei and other major oil fields. Ruishi has also established long-term strategic partnerships with these oil fields. We have been highly recognized for the stability of excellent product quality and timely and thoughtful service. The company’s products have been widely exported to North America, the Middle East, Russia, and other countries and regions.

“Excellent Quality, Honest and Faithful, Innovation, and Improvement, Satisfied Service”. Hebei Ruishi Bits Manufacturing Co., Ltd is willing to cooperate with customers honestly and obtain the result of a mutual win.

We strictly comply with the ISO9001 quality management system, ISO14001 environmental management system, and OHSAS18001 Occupational health and safety management system in the enterprise operation, and strictly implement API Spec7-1 quality management standards in the process of production.

Middle East Star Drill (MSD Co.) is the Exclusive Agency of HR BITS (HEBEI RUISHI BITS) for providing a wide range of Bit Types and Sizes in Iran and right now has a big project in the Iranian Offshore field for sales and bit engineering services as performance for RSS Bits. Also Right Now MSD can get Approval with good performance & Approval letter in ROP in the hardest condition in the ICOFC field in a 12 ¼” hole section with an average ROP recoded 7.66 m/hr. (1188 m in 155 hours in One Run) higher than other Western and Chinese brands of PDC Bits.

HR BITS (HEBEI RUISHI BITS) & MSD Co. can produce & supply a wide range of Bit Types and Sizes in Iran as follows:

- PDC Polycrystalline Diamond Drill Bits (Matrix & Steel Body)

- Three Cone Bits.

- Core Bits.

- Hybrid Bits.

- Bi-center Bits.

B- Drill Bit Services:

Using logically structured engineering processes built on a legacy of drilling experience and expertise, we analyze data from multiple offset wells to gain an understanding of possible performance barriers that can result in non-productive time (NPT) or invisible lost time. The result is a drilling plan that leverages advanced technologies and unsurpassed expertise to deliver an optimal drilling program and superior, in-field performance.

While drilling, we can continue to leverage our services to further refine real-time performance for longer, faster drilling runs than were previously impossible.

Bit selection involves choosing a bit that will do the job.

Bit Optimization involves finding the best bit for the job!

- Bit selection involves choosing a bit that will do the job. Bit Optimization involves finding the best bit for the job! With Bit Selection we are looking for a bit that will do the job and will do the job well. We want the selected bit and the way we operate it to do the best job possible, from the outset. This is rarely possible. Optimization builds on this fact, using our evolving understanding of an application to improve performance in a series of steps.

- Bit Optimization is a process that can be achieved if we work from the premise that bit performance can always be improved. The objective of drilling Optimization is to reduce drilling costs. This will be achieved by improving bit performance. There is a range of approaches we may use.

- Different running parameters

- Different bit selection

- Different bit features (Small changes)

- Different bit design (Large Changes).

C-Well Planning:

Providing the client with a drillable well design that meets their requirements is always the main goal of our well-planning engineers. This is achieved by close collaboration with our clients to fine-tune a good profile.

Our engineers provide technical support in the design, planning, and monitoring of wellbore proximity.

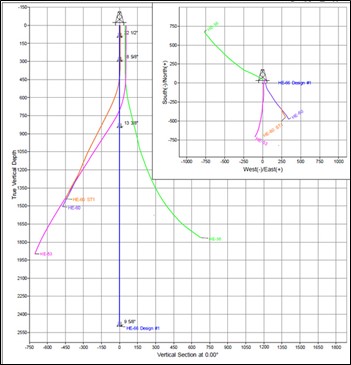

We use Compass software to design 2-D drawings that have a common reference to illustrate a designed wellbore trajectory.

C-1- Planning:

Plan the most accurate and cost-effective directional survey program to ensure wellbore placement within the drilling targets. Our well planners can provide planning for any type of well.

C-2- Anti-collision analysis:

Reduce drilling risk by minimizing the possibility of collision using wellbore positional uncertainty incorporated into the anti-collision analysis.

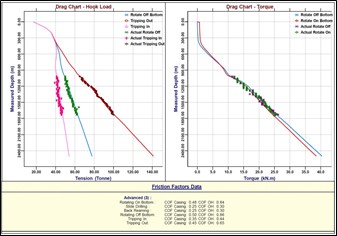

C-3- Torque & Drag analysis system:

The torque & Drag analysis system is used to validate well designs and prevent loss of rig time by eliminating drilling string failure. Our engineers can use the system to model all types of BHAs. Plan and analyze drilling, casing, and completion running operations, and assess the impact of predicted loads related to torque and drag. The main calculations are tension, torque, side force, fatigue, and tri-axial stress. A top-down analysis mode uses surface parameters to accurately understand forces acting along the string to the bottom of the well. It also accounts for the effect of hydraulic parameters such as fluid properties, flow rates, diverse fluid columns, and pressures. Temperature effects on the string also are considered for pipe stretch calculations. Riser less and inner-string configurations are modeled, as well as the effect of stand-off devices such as centralizers and friction reducers. Soft, stiff, or hybrid string models can be used for the analysis. Soft and stiff string analysis options allow the calculation of all the forces acting upon the BHA including torque, drag, stresses and side forces. The calculated loads are compared to string yield limits and rig operating limits and the results presented for fast identification of specific issues. Detailed graphical and tabular results provide a comprehensive description of the modeled scenario. Multiple user defined operating modes can be incorporated in a single calculation, allowing the entire drilling process to be modeled for a given hole section.

C-4-Hydraulic Analysis:

This module can be used to model pressure losses across the rig’s circulating system and pipe string, estimate equivalent circulating density (ECD) across the annular space, and analyze formation cuttings transport and its effect on pressure and ECD calculations. Temperature effect is also considered using four different rheological models, fluid compressibility, Fann® Viscometer readings at different temperature points, critical fluid velocity, and bit-nozzle size calculations for optimized rate of penetration. The module considers string eccentricity effect, pipe roughness, returns to the sea floor for dual gradient operations, and backpressure for underbalanced operations.