Our experience with horizontal and directional drilling gives E&P operators confidence in every project we deliver. Safe, accurate, reliable and experienced are just a few words our clients use to describe our crews.

Directional Drillers

Middle East Star Drill’s service professionals are fully-trained and capable of completing all required tasks before they are ever sent out on a job. Our directional drillers already know how to “make hole” when they come to Middle East Star Drill. They receive extensive software and service training relative to the geometry of directional work. Middle East Star Drill’s are paired with experienced senior staff to ensure our customers directional objectives are met or exceeded. Middle East Star Drill expects a level of on-site effectiveness so high that a Middle East Star Drill could function with only a calculator and a multi-shot survey tool.

EM-MWD/MWD/Gamma Operators

Middle East Star Drill uses a Four Level certification system for EM-MWD/MWD/Gamma operators to quantify their skill sets and match them with each project requirements. Recruits must have an electronics or IT background before being considered for placement in Middle East Star Drill’s training program. Completion of a rigid, in-house training and development program is required before they ever set foot in the field. This program intimately familiarizes them with all components of the EM-MWD/MWD/Gamma units and the applications software, ensuring their ability to accurately interpret tool readings, diagnose signal problems and trouble-shoot the system when necessary.

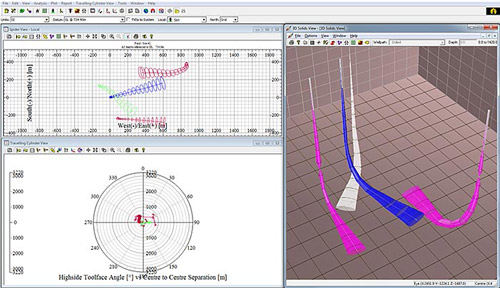

Directional Coordinators

Using the latest industry software, Middle East Star Drill coordinators prepare the directional plan, generate the wall plots and recommend BHA components. When required they can prepare collision avoidance and ellipse of uncertainty recommendations. Upon completion of the project the directional coordinator prepares a professional post-well report, providing the customer with all of the necessary wellbore data.

Service and Repair Specialists

Middle East Star Drill’s tool service group has the expertise in tool design/engineering, manufacturing and service to keep our tools operating at peak performance. We maintain complete quality control and do not send any MWD/Gamma components out for third-party repair. Motors are routinely sent back to the OEM (Original Equipment Manufacture) for stator reline or rotor repair and only OEM (Original Equipment Manufacture) replacement parts are used. Middle East Star Drill’s MTBF (Main Time Between Failure) is among the industry’s highest, correlating directly to keeping our directional costs among the industry’s lowest and that’s how Middle East Star Drill’s defines “performance-driven value.”