home

Bit Sales & Engineering Services

A-Bit Exclusively Sales of HR BITS (HEBEI RUISHI BITS) in Iran:

HR BITS (Hebei Ruishi Bits Manufacturing Co., Ltd) was established in 1990. It is engaged in diamond drill bit and drilling tool research and development, design and manufacture, sales, and service of specialized companies.

As the first-grade supplier for Sinopec, CNPC, and CNOOC, Ruishi’s products are widely used in the Tarim, Tuha, Changqing, Dagang, Sichuan, Zhongyuan,Jidong, Huabei and other major oil fields. Ruishi has also established long-term strategic partnerships with these oil fields. We have been highly recognized for the stability of excellent product quality and timely and thoughtful service. The company’s products have been widely exported to North America, the Middle East, Russia, and other countries and regions.

“Excellent Quality, Honest and Faithful, Innovation, and Improvement, Satisfied Service”. Hebei Ruishi Bits Manufacturing Co., Ltd is willing to cooperate with customers honestly and obtain the result of a mutual win.

We strictly comply with the ISO9001 quality management system, ISO14001 environmental management system, and OHSAS18001 Occupational health and safety management system in the enterprise operation, and strictly implement API Spec7-1 quality management standards in the process of production.

Middle East Star Drill (MSD Co.) is the Exclusive Agency of HR BITS (HEBEI RUISHI BITS) for providing a wide range of Bit Types and Sizes in Iran and right now has a big project in the Iranian Offshore field for sales and bit engineering services as performance for RSS Bits. Also Right Now MSD can get Approval with good performance & Approval letter in ROP in the hardest condition in the ICOFC field in a 12 ¼” hole section with an average ROP recoded 7.66 m/hr. (1188 m in 155 hours in One Run) higher than other Western and Chinese brands of PDC Bits.

HR BITS (HEBEI RUISHI BITS) & MSD Co. can produce & supply a wide range of Bit Types and Sizes in Iran as follows:

- PDC Polycrystalline Diamond Drill Bits (Matrix & Steel Body)

- Three Cone Bits.

- Core Bits.

- Hybrid Bits.

- Bi-center Bits.

B- Drill Bit Services:

Using logically structured engineering processes built on a legacy of drilling experience and expertise, we analyze data from multiple offset wells to gain an understanding of possible performance barriers that can result in non-productive time (NPT) or invisible lost time. The result is a drilling plan that leverages advanced technologies and unsurpassed expertise to deliver an optimal drilling program and superior, in-field performance.

While drilling, we can continue to leverage our services to further refine real-time performance for longer, faster drilling runs than were previously impossible.

Bit selection involves choosing a bit that will do the job.

Bit Optimization involves finding the best bit for the job!

- Bit selection involves choosing a bit that will do the job. Bit Optimization involves finding the best bit for the job! With Bit Selection we are looking for a bit that will do the job and will do the job well. We want the selected bit and the way we operate it to do the best job possible, from the outset. This is rarely possible. Optimization builds on this fact, using our evolving understanding of an application to improve performance in a series of steps.

- Bit Optimization is a process that can be achieved if we work from the premise that bit performance can always be improved. The objective of drilling Optimization is to reduce drilling costs. This will be achieved by improving bit performance. There is a range of approaches we may use.

- Different running parameters

- Different bit selection

- Different bit features (Small changes)

- Different bit design (Large Changes).

C-Well Planning:

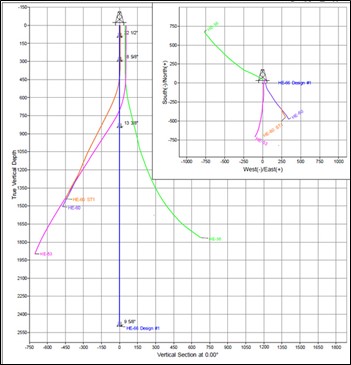

Providing the client with a drillable well design that meets their requirements is always the main goal of our well-planning engineers. This is achieved by close collaboration with our clients to fine-tune a good profile.

Our engineers provide technical support in the design, planning, and monitoring of wellbore proximity.

We use Compass software to design 2-D drawings that have a common reference to illustrate a designed wellbore trajectory.

C-1- Planning:

Plan the most accurate and cost-effective directional survey program to ensure wellbore placement within the drilling targets. Our well planners can provide planning for any type of well.

C-2- Anti-collision analysis:

Reduce drilling risk by minimizing the possibility of collision using wellbore positional uncertainty incorporated into the anti-collision analysis.

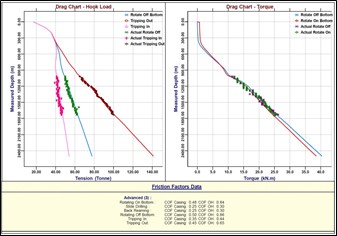

C-3- Torque & Drag analysis system:

The torque & Drag analysis system is used to validate well designs and prevent loss of rig time by eliminating drilling string failure. Our engineers can use the system to model all types of BHAs. Plan and analyze drilling, casing, and completion running operations, and assess the impact of predicted loads related to torque and drag. The main calculations are tension, torque, side force, fatigue, and tri-axial stress. A top-down analysis mode uses surface parameters to accurately understand forces acting along the string to the bottom of the well. It also accounts for the effect of hydraulic parameters such as fluid properties, flow rates, diverse fluid columns, and pressures. Temperature effects on the string also are considered for pipe stretch calculations. Riser less and inner-string configurations are modeled, as well as the effect of stand-off devices such as centralizers and friction reducers. Soft, stiff, or hybrid string models can be used for the analysis. Soft and stiff string analysis options allow the calculation of all the forces acting upon the BHA including torque, drag, stresses and side forces. The calculated loads are compared to string yield limits and rig operating limits and the results presented for fast identification of specific issues. Detailed graphical and tabular results provide a comprehensive description of the modeled scenario. Multiple user defined operating modes can be incorporated in a single calculation, allowing the entire drilling process to be modeled for a given hole section.

C-4-Hydraulic Analysis:

This module can be used to model pressure losses across the rig’s circulating system and pipe string, estimate equivalent circulating density (ECD) across the annular space, and analyze formation cuttings transport and its effect on pressure and ECD calculations. Temperature effect is also considered using four different rheological models, fluid compressibility, Fann® Viscometer readings at different temperature points, critical fluid velocity, and bit-nozzle size calculations for optimized rate of penetration. The module considers string eccentricity effect, pipe roughness, returns to the sea floor for dual gradient operations, and backpressure for underbalanced operations.

Contact US

Contact Information

Main Office:

Address: No. 182, 3rd Floor, Eastern Unit, Moqadas Ardabili St.,

Valenjak, Tehran, Postal code: 1985614147.

www.mestardrill.com

Email Address:

Alternatively, you can scan the following QR Code with your smart phone.

Technical Management:

Email: Deputy@mestardrill.com

Tools & Services

Whipstock Services

Use of Middle East Star Drill Co. Whipstock and milling tools offers to operators new alternatives to grass roots Directional & horizontal wells. The Middle East Star Drill Co. Whipstock is a quality built tool designed to prepare or “cut a window” in the casing of your existing well bore. Our Whipstock can be utilized in a vertical or high angle hole for sidetracking the original well bore or in preparation for directional or horizontal drilling. The reduction in cost per foot per recoverable barrel of oil has brought a new focus on oil in place reserves. The Middle East Star Drill Co. whipstock is designed to cut a window in the casing of the existing wellbore. This design allows the tool to be run in vertical or high angle holes. We have two type of whipstock:

1- One Trip Case Hole Whipstock :

In this type to save time, systems can accomplish all sidetracking tasks in one trip. On the first trip in the hole, both styles of the Whipstock are lowered by way of the starting mill, orientated to your predetermined direction, anchored, and initial milling of the casing window is begun. The completion of the casing window is achieved on subsequent mill runs. In this system following operation done in one stage:

Start the window mill

Complete the mill

Clean up

2- Two Trip Case Hole Whipstock :

2-1- Method of Application for Window Cutting, There are 5 Steps:

Initial step, clamping, cutting through, window service and drilling testing. Operating parameters for every steps as per manufacturer and supervisor Guideline.

Connect the milling cone for sidetrack window-cutting and drilling tools as their designs require.

Drill down the drilling tools to 2~3 meters up the deflector, speed of drilling down should be not faster than 30 pieces/hour. Connect the Kelly bar.

Run the pump to circle the drilling fluid, start the rotary table at a low speed, and record its hanging weight, drill down the drilling tools slowly until the hanging weight changes. Record its depth at this moment.

Start the construction of initial step, clamping, cutting through by the parameters of milling cone.

Trip the drilling tools slowly for the window service as stipulated until there is no jam and blockage.

After window service, start the tentative drilling.

After all the above mentioned operations, first, flush the wall fully, and then put the drilling tools out of the hole.

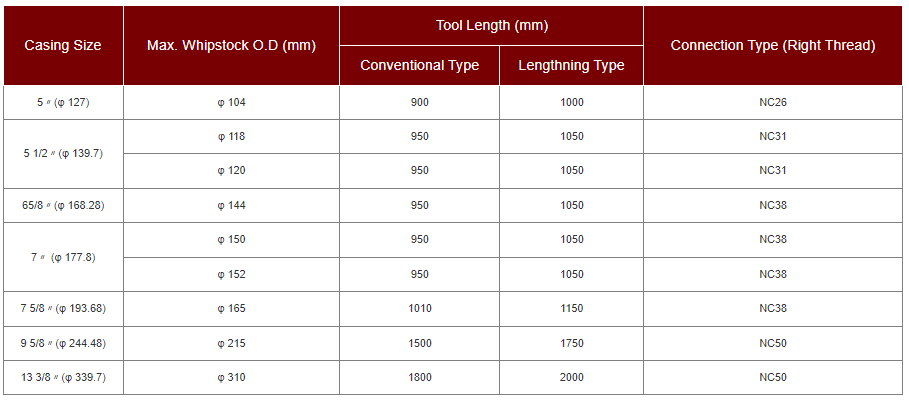

2-2- Basic Parameters and Performance Data:

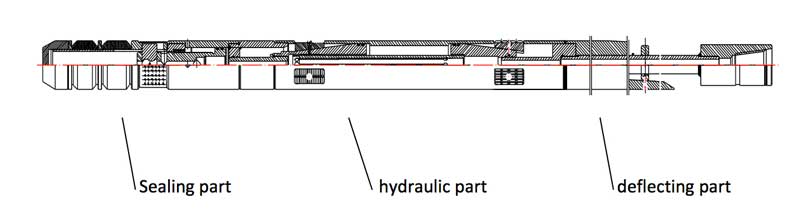

The main structure consists of deflecting part, hydraulic part and sealing part (optional) as following pictures.

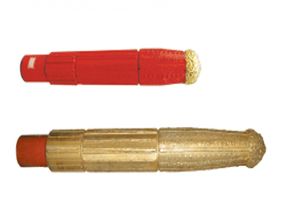

Milling Structure for Window Opening

Sidetrack window-cutting make use of milling cone and deflector inside of the case pipe. By design, the shape, cutting bezel and alloy are optimized. The milling cone for sidetrack window cutting can finish window cutting and window service at one time together, speed up the construction, and meet the requirements of site work.

The milling cone for sidetrack window-cutting is a combined type. There are three stages: window cutting, window service, stabilizing window. Use proper piece of hard alloy and hard alloy electrode according to different stages, make the best matching between speed and service time to the maximum extent.

Tools & Services

Survey Services (Single shot, Multi-shot & Gyro)

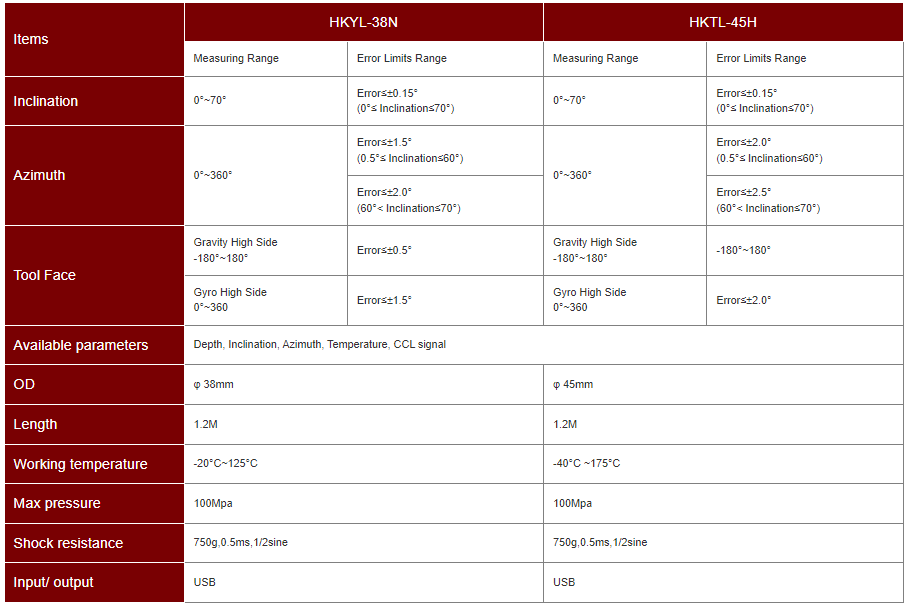

Middle East Star Drill has HKTL Series Gyro Inclinometer that have following advantage:

HKLT series dynamically turned gyroscope inclinometer is a new precision gyroscope inclinometer system, particularly the use of the following engineering work:

Magnetic interference from wells around the obstacle orientation

Infill drilling measurement and in the casing completion within or drill pipe measurement.

Old well window directional

Old well trajectory repetition measurement

Metal well drilling orientation measurement

Salt to the well-connected orientation

Oriented perforating

The main engineering application of HKTL Dynamically Tuned Gyro inclinometer include:

Deflecting

Orientation

Well Trace Measurement

Tools & Services

LWD Services

Maximize your reservoir value with LWD solutions

Our LWD systems offer superior formation evaluation data to maximize reservoir value while drilling. LWD sensors deliver wire line quality petrophysical data and address directional drilling, formation evaluation, and geosteering applications. Our tools will help you gather reservoir information, enhance drilling performance, and optimize well placement.

Gamma services are probe-based or collar-mounted with our MWD service. Gamma-ray sensors detect lithology changes.

Resistivity services are offered through our system, delivering comprehensive evaluation of formation and near-bore environments.

Our Reservoir Navigation Services use real-time LWD formation evaluation sensors with directional data and formation models to properly target your drilling assembly. This ensures optimal entry to maintain the wellbore in the zone of maximum interest, predicting and avoiding reservoir exit. Azimuthal imaging also is available.

Middle East Star Drill’s LWD system consist from two famous manufacture:

GE LWD

BOTE LWD

Tools & Services

MWD/EM-MWD Services

MWD Services

Measurement While Drilling (“MWD”) systems are installed in the drill string to provide real time measurements of basic trajectory parameters such as inclination, direction, tool-face and temperature. Additional sensors such as pressure, gamma-ray and resistivity may be added depending upon the specific application.

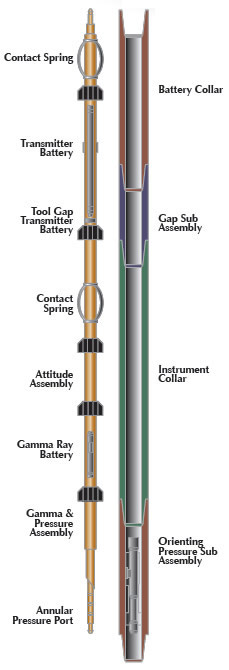

MWD tools consist of three basic sections:

Power Supply – Most tools are powered by lithium batteries or in some cases down-hole generators (turbines).

Sensor Section – Hole trajectory is measured by a sensor stack that has three accelerometers and three magnetometers. The inclination and roll (gravity tool-face) of the tool is made by gravity based measurement devices called accelerometers. Simply stated, they can be considered to be an electronic plumb-bob. Magnetometers measure the earth’s local magnetic field. Combined with inclination sensors the tool can provide a reference direction to magnetic north. This is corrected for true north by adding the localized value for magnetic declination. Other sensors such as pressure, gamma-ray, and resistivity are typically housed in separate dedicated tool sections.

Transmitter – Current MWD tools transmit in two basic manners, by sending pressure waves through the drilling mud (mud pulse) or by transmitting electromagnetic (EM) signals through the earth to surface.

Mud Pulse System

Mud pulse tools operate by either opening or closing a valve in the tool that creates either a pressure surge (positive pulse) or drop (negative pulse). Mud pulse systems are a reliable transmission method.

Gamma

Gamma ray sensors measure the natural radioactive emissions from isotopes of potassium and the uranium and thorium series contained in, or absorbed into the mineral components of surface rocks.

Middle East Star Drill’s MWD system consist of three type of famous MWD:

Tolteq MWD (Positive)

GE Tensor MWD (Positive)

Bench Tree MWD (Positive)

All type can work up to 175 °C.

EM-MWD Services

Electro-Magnetic MWD systems:

Use the same basic sensors and power supplies as the mud pulse systems. The main difference is in the transmission of data. Rather than using the drilling mud to send pressure waves, the tool sends either a magnetic pulse or electrical current through the ground to the surface. On surface the data is received through ground antennas and the data processed. EM systems are significantly faster (10x) than conventional mud pulse. In addition data can be sent at any time (not just when the rig pumps are circulating). The net result is faster overall drilling times. In addition the EM systems are the only practical method to drill underbalance wells involving the use of air, nitrogen, and foam. EM systems have no moving parts and do not create significant restrictions in the drill string. As a result the reliability is significantly higher, and damage from erosion caused by drill solids is minimal. EM tools do have depth limitations which are a function of how much power can be supplied by batteries for the duration of the drilling interval, and at higher power settings the battery costs may be significant.

Electromagnetic Measurement While Drilling “EM MWD” Services:

The EM MWD tool is a wireless MWD System which utilizes low frequency current-loop signals to communicate data to the surface. The EM tool is installed in the BHA and injects electric current into the formation downhole while drilling. An antenna (ground stake) is driven into the surface, which measures the voltage differential (potential) between the stake and a line tied into the casing on the drilling rig. This signal is processed thru surface computers to decode the downhole data. EM signals are not affected by the drilling mud properties or rig pumps and have a significantly higher data rate than mud pulse systems.

Applications:

Underbalanced Drilling

Coal Bed Methane

Production

Draining for HSE

Draining for HSE

Lost Circulation

Vertical Control Drilling

Directional Drilling

Horizontal Drilling

Re-entry Wells

Contaminated mud systems

Features:

The EM MWD tool can be operated at a variety of frequencies, allowing for either high data rate, or extended depths (over 3,500 m) without the need for repeaters or long wire systems. Advanced digital filtering techniques allow two or more rigs to drill on the same pad without interfering with each other’s signal transmission. The tool has directional, gamma ray, and pressure sensors, making it versatile enough to accommodate most of your directional and underbalanced drilling requirements. The wireless communication operates independent of rig pumps and creates virtually no additional pressure restrictions in the BHA. Access to the microprocessor can be made through a unique side entry data port on the rig floor. Simply plug into the tool to program it, retrieve recorded data, or put it to sleep between wells to conserve battery life. The instrument section may be left in the non-magnetic collar between wells or during casing breaks to save rig time handling tools. The EM tool has become a full service tool and able to have “talk down” capability. The tool can be fully controlled from the surface, changing data rates, transmission formats, power levels etc, while drilling.

Middle East Star Drill’s EM-MWD system consist of:

BesTrack EM-MWD System(EMWD-45)

NOV Black Star EM-MWD System

The Blackstar & Bestrack EM is an MWD tool that combines the latest in electromagnetic frequency based technology with a durable and efficient design, providing an effective solution for EM applications.

Directional survey and steering only or optional gamma logging configurations with annular pressure capabilities are available. Programmable low frequency transmission and high-power output can significantly reduce noise sources for a clean signal. No mechanical parts reduce transmission problems in the presence of LCM. Down hole tool is fully retrievable and re-insertable for added confidence in lost in hole conditions. Continuous transmission and automatic resynchronization of survey and steering sequences eliminates the need to cycle pump for survey acquisition or tool face mode.

Applications

Features & Benefits

High operating temperature (175C) and pressure (20,000psi)

Wireline retrievable and reinsertable design (minimum 2.25in I.D.)

Available real-time gamma and annular pressure for LWD

Downlink capability for frequency and power settings

High-speed data transmission

Data transmission independent of pump pressure

Reduced lost circulation material (LCM) restrictions

Programmable frequency settings for noise elimination

Reduced mechanical parts for improved reliability and ruggedness

Continuous survey and steering frames automatic resynchronization

Specifications:

Directional, vertical, horizontal and re-entry wells

Logging While Drilling (LWD), gamma, annular pressure, vibration

Aerated and contaminated drilling fluids

Underbalanced drilling (gas, air, foam)

Lost circulation zones

High rate of penetration (ROP) applications

Coal bed methane (CBM)

Tools & Services

Mud Motors(PDM) Services

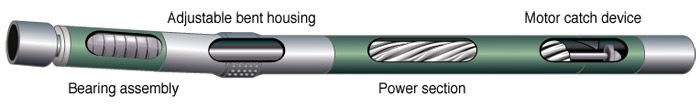

Middle East Star Drill carries a full range of tool sizes from 3 1/8 inches OD through to 11 1/4 inches OD with various lobe configurations in different stages due to clients drilling conditions. This enables Middle East Star Drill coordinators to specify the right motor for the project with regard to hole size, displacement objectives, available pump capabilities and fluid properties. This range of directional motors enables Middle East Star Drill to specialize in hole sizes ranging from 4 1/8 inches through 26 inches.

Rig site adjustable housings ensure rig site flexibility and reduced on-site storage.

directional motors are equipped with a field-adjustable housing that allows for easy and reliable bend adjustment from zero (or straight) to three degrees in 12 increments. The tensile strength of this adjustable housing meets or exceeds the rest of the motor to ensure uncompromised tool integrity. Middle East Star Drill’s adjustable housing features a 120 degree wear pad as an integral part of the adjusting ring. Regardless of the bend angle, the wear pad will always be opposite high side to ensure reliable directional performance.

Drive shaft and universal joints designed to withstand the rigors of variable torque applications.

Middle East Star Drill directional motors employ the latest technology in drive shafts and universal joints. This key assembly converts eccentric rotation from end of the rotor to concentric rotation through the bearing assembly to the bit box mandrel. Pressure compensated sealed bearing universal joints on each end of the shaft contribute to the motors reliability and run longevity.

Power section quality and selection ensure the right torque and rotary speed combination for optimal performance.

Middle East Star Drill directional motors are available with different power section options to handle a wide range of directional applications. Whether the job calls for high speed low torque, medium speed medium torque, low speed high torque, invert mud systems or drilling with air, you can rely on Middle East Star Drill’s professional operations team to assemble the right power section for optimum directional performance. The rotors and stators are cleaned, callipered, measured, inspected and cataloged after every job to ensure that all components are well inside the manufacturer’s recommended specifications.

All PDM Stabilization and wear pads are part of the proprietary directional assembly design provided by Middle East Star Drill.

Middle East Star Drill directional motors can be configured with a near bit stabilizer as part of the bent housing assembly to provide closer proximity to the drill bit. Stabilizers can be spiral or straight blade, and when run in conjunction with the integral wear pad at the bend, provides the full range of stabilization required for any directional plan.

Dump sub reliability ensures trips will be dry and quick/efficient.

This component, located at the top of the motor, is a normally-open valve which allows mud to by-pass the motor to fill the hole or drain the pipe when tripping. The valve will automatically close when pumping starts.

Middle East Star Drill`s PDM Systems consist of three type of famous PDM:

DynoMAX PDM

Cougar PDM

LILIN PDM